SUMMER 2023 CRAFT QUARTERLY "CHANGING CLIMATE/CHANGING PRACTICE"

CLIMATE COLLABORATION: THE EMERGENCE OF COBB MOUNTAIN ART & ECOLOGY PROJECT

An overview of ceramicist Scott Parady's blended approach to art and ecology living in Northern California's wildfire prone climate.

Read Full Article HERE

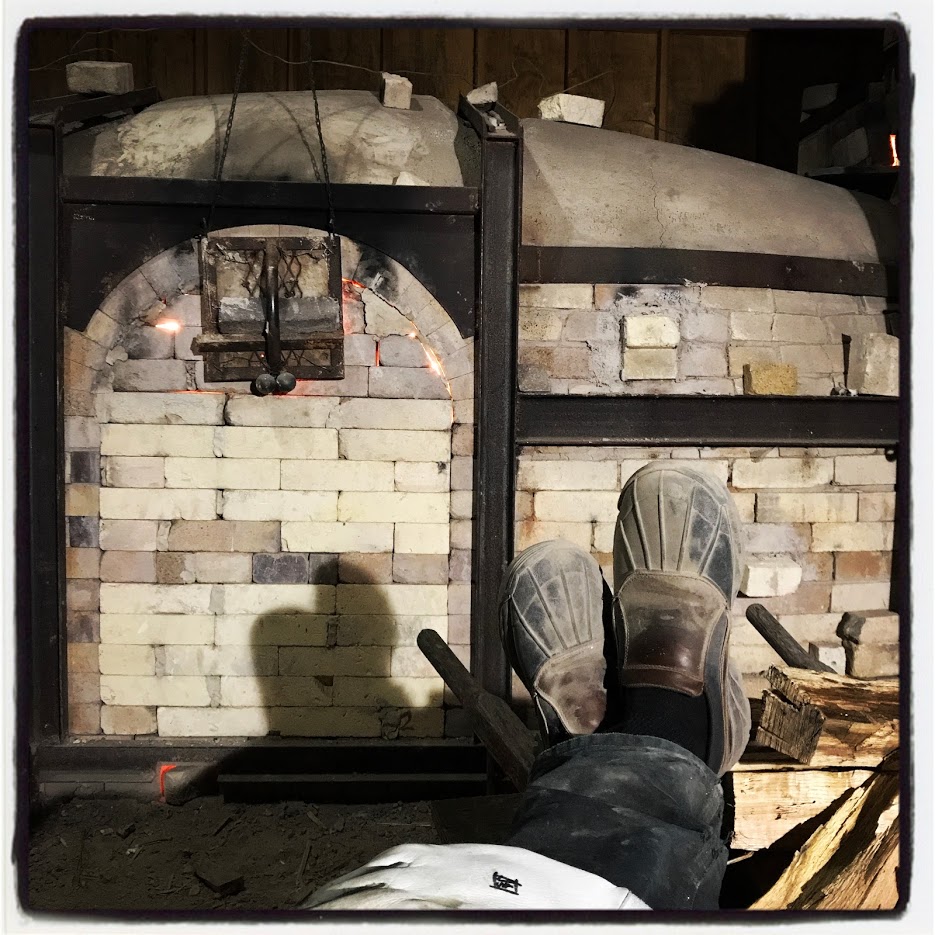

Anagama Build Workshop

Last week we started building our long talked about anagama kiln. We had a great crew with a variety of experience acting under the direction of Scott Parady and Nick Schwartz. During the seven day workshop students excavated and leveled the foundations, laid the floor, build the floor, firebox, walls, arch form, base of the stack, and got about a third of the way through the arch. There is still plenty to do at the moment and we are working on the kiln bit by bit with the goal of firing in early January. The kiln itself will have a ware chamber that is around 20 in depth with a maximum width and height of around 4.5 feet. There is a secondary chamber being built into the stack to help reduce smoking. We will update photos as we continue to work on the kiln.

Enjoy!

CMAEP Staff

New Year to Spring.

We're still getting a little bit of the winter weather but we have our seedlings started and have been working on getting the property ready for the summer by cutting in new fire breaks, clearing undergrowth and low limbs, and doing ground burns all as fire prevention measures for the summer. We have also been firing off our kilns and getting the upstairs living area ready for flooring. We are looking forward to a new group of residents coming in later in the year and have a studio sale and open house planned for May 19th & 20th, more to come on that in other posts.

We are also staring up classes again. This month Jules Stout has been teaching a kids class and a adult handbuilding class. Our classes will continue through the summer and into the fall. Here are some photos that Artist in Residence HP Bloomer has taken over the last few months.

Enjoy!

CMAEP

Clays From Around Cobb Mt

By HP Bloomer

05.14.2017

Originally published on his blog: Bloomerpottery.wordpress.com

These are a few clays that I have tested for shrinkage and temperature range from around the Cobb Mountain Arts & Ecology Project area. This area is rich in volcanic activity and many of the clays are derived from rhyolites, which are silica rich volcanic rocks, formed during those actives. It would seem that several of them are quite similar when fired but will often have slight nuances in texture and particle size or inclusion. These are all tests that I ran a few months back and am just getting to publishing now. All tests were run in electric/oxidation except for the final cone 10 tiles which were fired in gas reduction. There are a few more clays that I have not shared in this post but may add later on. I hope that this can become a resource for future makers in the Cobb area and a inspiration for those of you who are interested in finding local clays.

Adams Springs Bluff Clay

GPS: 38.857996, -122.719689

Very coarse grained clay that begins to vitrify at cone 6 and starts sticking to surfaces at cone 10. It may need some amending to be workable but has a lot of potential. I did not make a shrinkage bar for this clay.

Big Creek/175 Wash Out Clay

GPS: 38.857517, -122.722183

This is a very fine but slightly sandy clay found in the banks of Big Creek as it intersects CA Highway 175 less than a mile from Cobb Mountain Arts & Ecology Project. Because it is from active alluvial deposits its reliably is questionable. It begins to become vitrified around cone 6 and starts sticking to the shelf at cone 8. By cone 10 the clay has become glossy and is more actively fluxing. This was not tested for shrinkage.

Bottle Rock Road Dark Brown Clay (mile marker 3.6 East Side of road)

GPS: 38.899102, -122.790808

A very sticky dark chocolate brown when raw and full of obsidian inclusions from the east side of the pull out at Bottle Rock road near mile marker 3.60. In tests the clay started vitrifying after cone 6 and started sticking to the shelf/trays around cone 8 although this might have been due to the melting of the pervasive obsidian inclusions common to clays from this source. This clay was not tested for shrinkage.

Bottle Rock Road Light Brown Clay (West side of road near mile marker 3.60)

GPS: 38.898739, -122.791109

This is a very sticky clay very similar to the dark brown clay. It is slightly lighter in color when raw but fires to the same statistics as the dark brown. It is undoubtedly the same vein of material as the previous clay although it may be easier to source as it is more readily available at the surface. It still has quite a bit of obsidian in it and would need to be screened. No shrinkage information is available for this clay.

Bottle Rock Road Clay 1

GPS: 38.898559, -122.791181

This clay comes from a feeder creek that runs parallel to the west side of Bottle Rock road and empties into the source for the dark and light brown clays previously mentioned. Although it fires to a much lower temperature it is much cleaner and has much less obsidian in it. It vitrifies around cone 3-4 and bloats and melts after cone 5. It would make a nice clay body for anyone working at cone 2-3 and with some amendments could certainly be useful at cone 5. The source is easily dug and just off the road. No shrinkage tests were done for this clay.

Bottle Rock Road White Inclusion Clay (mile marker 3.60)

GPS: 38.899108, -122.791128

This very white, sticky, and plastic clay is found in small inclusion in the sandy obsidian riddled cliff at the mm 3.60 pull out on Bottle Rock road. It is a very sandy but very nice clay but does not come in any great quantity and using it as a source material may add to cliff deterioration. It begins to vitrify at cone 8 and is nice even up to cone 10. No shrinkage data was collected for this clay.

Bottle Rock Road North (mile marker 1.9)

GPS: 38.920129, -122.804331

This is a very nice, smooth, fine clay from just north of the previous Bottle Rock samples. It is on the west side of Bottle Rock road and just before another sandy white exposure. The clay is underneath a grassy outcropping and is a yellowish tan color when raw. With a little testing and work it would be a good low to midrange clay. Although the test samples we took were relatively free of any obsidian inclusions it might need a little bit of screening to insure that all debris is removed. This clay seems to loose its porosoty around cone 4-5 and by cone 6 it is starting to bloat and become brittle. All samples fired to cone 8 & 10 were unidentifiable puddles. so it might work well as a glaze component.

Shrinkage: Cone 01: 5%, Cone 2: 10%, Cone 4: 11.5%, Cone 6: 9% (at cone 6 it starts bloating and expanding.)

Glenbrook Clay

GPS: 38.852581, -122.757539

This is another clay from Bottle Rock Rd here in the Cobb area. Its less than 3 miles from the Cobb Mountain Arts & Ecology Project and accessible from a road cut. The Glenbrook clay is on the east side of Bottle Rock near the Glenbrook intersection. It fires very similarly to the previous Bottle Rock sample from mile marker 1.9 but is slightly redder and melts at a lower temperature. It has a very nice and slightly sandy quality and would be nice for working with in the cone 1-2 temperature range. It was porous in tests up to cone 4 and then bloated and slumped but cone 6. So it is a very open clay body that could use some amendments if one wanted to use it in their work. The cone 8-10 tiles melted completely and might be suitable as glaze components for those working at that temperature.

Shrinkage: Cone 01: 5%, Cone 2: 6%, Cone 4: 6%, Cone 6:8%

Running Trail Clay 1

GPS: 38.857720, -122.731303

The Running Trail Clay is from a property that abuts the Cobb Mountain property to the south and may be part of the parent material for the Big Creek Clay. This clay is pretty irregular in particle size and has a 10-12% shrinkage rate. Although it holds together quite well up to cone 6 it does crack quite a bit making it impractical for functional items but potentially useful for sculptural use. In these tests the clay had completely vitrified by cone 6 and started sticking to the test trays by cone 8. It may need some kaolin additions to make it a workable cone 10 clay.

Shrinkage: Cone 01: 10%, Cone 2: 12%, Cone 4: 12%, Cone 6: 10%, shrinkage bars warped and were unreadable beyond cone 6.

South Side Parady Property Clay 1

GPS: 38.859771, -122.727677

This is a extremely thixotropic clay from the south most side of the Cobb Mountain property. It would need to be blended with a more utilitarian clay to make it it workable but might provide a source of clay to use for amending shorter, lower firing clays. It has some inclusions in it and would need to bee screened before use. It seems to be relitively refractory as far as clays in this area go and only starts to vitrify at cone 8. It has a relitively low shrinkage rate coming in under 10% up to cone 8.

Shrinkage: Cone 01: 7.5%, Cone 2: 8%, Cone 4: 8%, Cone 6: 9.3%, Cone 8: 9.5%

South Side Parady Clay 2

GPS: 38.859771, -122.727677

This is a clean (obsidian free) but slightly short clay just a few meters away from the previous sample. It is exposed in a road cut along the firebreak that defines the south side of the property. It has a slightly higher shrinkage rate than the previous sample but is much more workable. This clay starts vitrifying at cone 6 and is vitreous by cone 8. Both this sample and the prior are slightly less accessible and would require bagging and a hike up a steep hill to access.

Shrinkage: Cone 01: 10%, Cone 2: 11%, Cone 4: 11%, Cone 6: 12%, Cone 8: 12%, Cone 10: 12.5%

Well that is all the clays I have tested from the area thus far. I hope you enjoyed the results.

Sheep & Goat Pen, Aquaponic Garden & Koi Pond, & 3rd Soda Kiln Firing

Its been a busy week here. We have had nearly 6" of rain or snow in various combinations over the last two weeks and everything is saturated. Thankfully we with a break in the weather since Thursday, we have been getting some work done around the property.

We purchased 6 lambs this week which Elliott will be raising until April or May and then selling off for meat. Because of these new guests on the land we constructed a larger livestock pin. Elliott, HP, Sierra & Mitch put up a 65 foot by 20 foot enclosure over the last couple of days. This enclosure which is next to the main garden will be home to the sheep as well as Freckles and Ramsey, our two goats.

Scott continued the finishing of the Aquaponic garden and Koi pond. The last several weeks have been dominated by work on this project. The final waterproof coatings were added several weeks ago and with every break in the weather, rocks were cut to fit and plans made for final details. Scott and all of the residents, as well as a few helpers from Sacramento, have been diligently and tirelessly working on mortaring everything in place since Thursday. We very much look forward to the completion of this project.

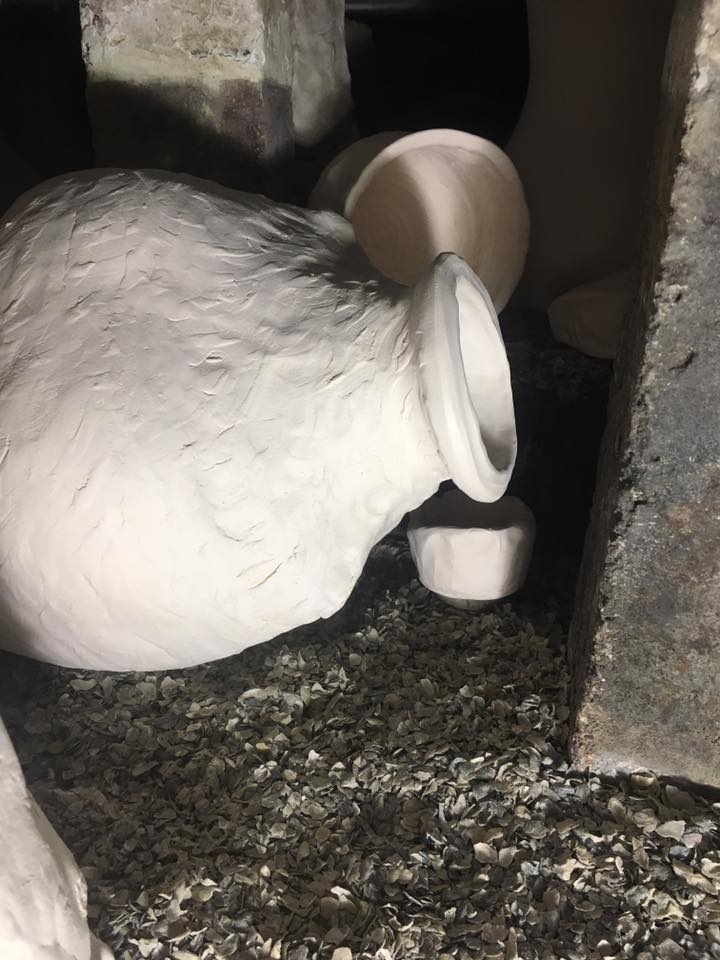

In other news around the studio, the soda kiln was also fired for the third time by resident artist HP Bloomer. It seems like it was a fairly successful firing that used both wood and gas. We will also hopefully be changing out the orifices in the Bailey gas kilns this week and getting them up and running.

Thanks for stopping by!

Updates Summer through Winter 2016

We are currently updating and reorganizing the website. We will be moving the updates and most current posts to the blog. So this first post will be a recap of info that is already on the current project overview with a few new tidbits.

Best,

HP

At present: This summer we welcomed our first complete group of 6 resident artists whom have been involved in making their work as well as helping around the property. The residents' three bedroom house is complete, and the 1800 sq ft barn just needs doors and a wood stove. This barn building is for firewood storage and preparation, wood working, clay and equipment storage, as well as clay mixing.

The 5000 sq ft studio and kiln building have passed final inspection and we will begin work on the loft section of the studio this winter. The train kiln's inaugural firing in May 2015 was smooth and the results were very good and it has been fired successfully a number of times since. In November of 2016, we completed the wood/gas, soda kiln and have fired it twice. We will begin construction of the anagram kiln this winter and plan to fire as soon as it is complete. We have also installed two Bailey updraft gas kilns along with a Cress electric kiln as well as having built a small woodfired pizza oven at the studio.

Other projects of interest include an 8,000 gallon water tank, which we installed in October and plumbed up to a property wide fire suppression system. In November, we began working on a 10,000 gallon koi pond that is tied into a aquaponic garden and the fire suppression system. We are currently busy with clearing brush and trimming trees in order to maintain a fire safe property. The residents have also been gathering, splitting and storing wood to heat the studio and resident house as well as for firings.

This spring we are looking forward to installing mushroom beds as well as doing more work in the newly terraced, fenced and irrigated garden. In April, we will also be introducing a beehive to the garden and hopefully a second bee colony in the orchard eventually.

Future near and far: As soon as the studio is functional the plan is to construct a ¾ acre pond just south of the studio. The pond will serve as fire protection, plant and wildlife habitat, and an opportunity to farm fish as part of a sustainable lifestyle that will be practiced and explored on the property. Up the hill from the resident complex will be the demonstration garden and nursery. The more successful trees and plants from around the property will be propagated and made available to the public.